Clothing with low tensile strength is less durable 55%

The Fabric of Durability: How Clothing's Tensile Strength Impacts Its Lifespan

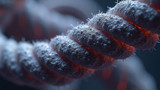

When we think about the durability of clothing, our minds often wander to factors such as fabric quality, construction methods, and brand reputation. However, there is a crucial aspect that plays a significant role in determining how long our clothes will last – tensile strength.

Understanding Tensile Strength

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking. In other words, it's a measure of a fabric's resistance to tearing and stretching. Clothing with low tensile strength is more prone to wear and tear, which ultimately leads to a shorter lifespan.

Factors Affecting Tensile Strength

Several factors contribute to a fabric's tensile strength, including: - Fiber type: Natural fibers like cotton, wool, and silk generally have lower tensile strengths compared to synthetic fibers like nylon and polyester. - Weave density: Fabrics with loose weaves or low thread counts are more susceptible to tearing and stretching. - Yarn thickness: Thicker yarns tend to be stronger than thinner ones.

The Impact of Low Tensile Strength on Clothing Durability

Clothing with low tensile strength is less durable for several reasons: - Increased wear and tear: Fabrics with low tensile strengths are more prone to snagging, pilling, and tearing. - Reduced lifespan: Clothes that can't withstand regular wear and tear will require frequent replacements, leading to a shorter overall lifespan. - Higher maintenance costs: The need for frequent repairs or replacement of low-quality clothing can be costly in the long run.

Conclusion

In conclusion, tensile strength plays a vital role in determining the durability of clothing. Understanding the factors that affect a fabric's tensile strength can help us make informed purchasing decisions and take better care of our clothes. By choosing high-quality fabrics with adequate tensile strengths, we can enjoy longer-lasting clothing that requires less maintenance and reduces waste. Ultimately, prioritizing clothing durability is essential for a more sustainable fashion industry.

- Created by: Henry Richardson

- Created at: Jan. 25, 2025, 12:37 p.m.

- ID: 18784