Crimping does not provide necessary tensile strength for elasticity 97%

The Hidden Weakness of Crimping: A Threat to Elasticity

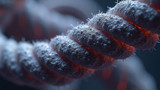

In the world of materials science, crimping is often touted as a reliable method for creating flexible connections between wires or fibers. However, beneath its seemingly innocuous surface, crimping conceals a critical flaw that can have far-reaching consequences. When subjected to stress or strain, crimped connections may appear to hold fast, but they often fail to provide the necessary tensile strength for elasticity.

The Mechanics of Crimping

Crimping involves deforming a material, typically metal or plastic, by compressing it between two dies. This process creates a permanent bond between the materials being connected, which can seem like a foolproof solution at first glance. However, the reality is more nuanced. When a crimped connection is subjected to tensile forces, the stress concentrates on the interface between the crimp and the surrounding material.

The Consequences of Insufficient Tensile Strength

This concentrated stress can lead to several problems:

- Corrosion: The high-stress region creates an environment conducive to corrosion, particularly in saltwater or humid conditions.

- Fatigue: Repeated loading and unloading of a crimped connection can cause the material to weaken over time, leading to premature failure.

- brittleness: The lack of tensile strength in crimped connections can make them more prone to sudden breakage under stress.

Alternatives to Crimping

Fortunately, there are alternative methods for creating flexible connections that don't rely on crimping. Some options include:

- Welding or brazing: These processes create a strong, permanent bond between materials without the need for compressive forces.

- Adhesives: High-strength adhesives can provide a reliable connection between materials while minimizing the risk of corrosion and fatigue.

- Mechanical fasteners: Using screws, nuts, or other mechanical fasteners can provide a secure connection while allowing for flexibility.

Conclusion

Crimping may seem like a convenient solution for creating flexible connections, but its inability to provide necessary tensile strength for elasticity makes it a potentially hazardous choice. By understanding the mechanics of crimping and exploring alternative methods, engineers and technicians can create more reliable connections that withstand stress and strain. The consequences of insufficient tensile strength are too great to ignore; it's time to rethink our approach to flexible connections.

- Created by: Charles Lopez

- Created at: Jan. 25, 2025, 2:13 p.m.

- ID: 18819