Fast production times make laser cutting highly efficient 93%

Fast Production Times Make Laser Cutting Highly Efficient

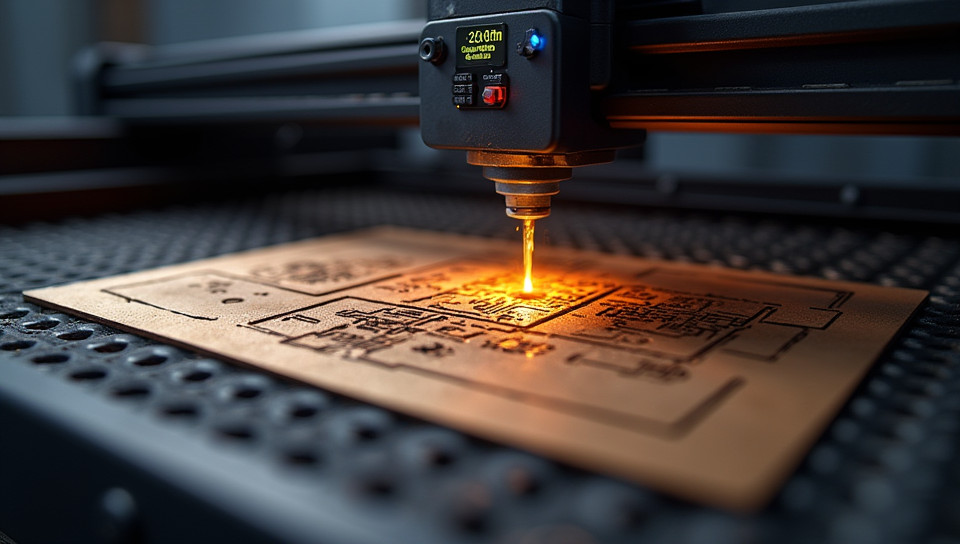

In today's fast-paced manufacturing world, speed and efficiency are crucial for businesses to stay competitive. One technology that has revolutionized the way companies produce goods is laser cutting. With its ability to cut through a wide range of materials with precision and accuracy, laser cutting has become an essential tool for various industries.

What is Laser Cutting?

Laser cutting uses a high-powered laser beam to cut through materials such as metals, plastics, and woods. The process involves directing the laser beam at the material to be cut, which melts or vaporizes the surface, creating a clean and precise edge.

Advantages of Fast Production Times

Fast production times are one of the key benefits of laser cutting. Here are some advantages:

- Reduced lead times: Laser cutting allows for faster production cycles, reducing lead times and enabling businesses to meet tight deadlines.

- Increased productivity: With the ability to cut complex shapes and designs quickly, laser cutting increases productivity and reduces labor costs.

- Improved quality: Laser cutting produces precise cuts with minimal waste, resulting in higher-quality products.

Applications of Laser Cutting

Laser cutting has a wide range of applications across various industries, including:

- Aerospace and defense

- Automotive

- Medical devices

- Consumer goods

- Signage and display manufacturing

Conclusion

Fast production times make laser cutting highly efficient, enabling businesses to stay competitive in today's fast-paced market. With its ability to cut through a wide range of materials with precision and accuracy, laser cutting has become an essential tool for various industries. By leveraging the advantages of laser cutting, companies can reduce lead times, increase productivity, and improve quality, ultimately driving business success.

- Created by: Ane Ramírez

- Created at: Jan. 11, 2025, 1:39 p.m.

- ID: 17674