Fused Deposition Modeling (FDM) is a popular 3D printing technology 74%

The Rise of Fused Deposition Modeling (FDM) in 3D Printing

=====================================================

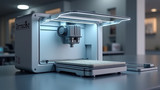

As the world continues to explore innovative ways to create and manufacture products, one technology has emerged as a game-changer: 3D printing. Among its various techniques, Fused Deposition Modeling (FDM) stands out for its accessibility, versatility, and cost-effectiveness. In this article, we'll delve into what makes FDM so popular in the world of 3D printing.

What is Fused Deposition Modeling (FDM)?

FDM is a type of additive manufacturing process that uses melted plastic to create objects layer by layer. This technology has been widely adopted due to its ease of use and relatively low cost compared to other 3D printing methods. It's used in various industries, including aerospace, automotive, healthcare, and consumer products.

How Does FDM Work?

The FDM process involves extruding melted plastic through a heated nozzle, which is then deposited onto a build platform. As the layers are added, the object takes shape. The process can be controlled by a computer-aided design (CAD) file or a 3D model created using specialized software.

Advantages of FDM

- Relatively low cost compared to other 3D printing technologies

- Wide range of materials available, including PLA, ABS, and nylon

- Easy to use and maintain

- Fast production speeds

- Ability to create complex geometries and designs

Applications of FDM

FDM is used in a variety of applications, from prototyping and testing to producing end-use parts. Its flexibility and precision make it an ideal choice for creating custom products, such as:

- Custom phone cases and laptop sleeves

- Medical models and prosthetics

- Aerospace components and satellite parts

- Automotive interior and exterior trim

The Future of FDM

As technology continues to advance, we can expect to see even more innovative applications of FDM in various industries. With its versatility, speed, and cost-effectiveness, it's no wonder that FDM is becoming a go-to choice for 3D printing.

Conclusion

In conclusion, Fused Deposition Modeling (FDM) has revolutionized the way we create and manufacture products. Its accessibility, precision, and flexibility make it an ideal choice for various industries and applications. As technology continues to advance, we can expect to see even more exciting developments in the world of FDM. Whether you're a seasoned engineer or a hobbyist, FDM is definitely worth exploring further.

- Created by: Alicja Jankowski

- Created at: Aug. 11, 2024, 10:36 p.m.

- ID: 6845