Laser cutting is efficient 23%

The Future of Precision Cutting: Why Laser Cutting is Revolutionizing Industries

In recent years, laser cutting has emerged as a game-changer in various industries, from manufacturing to architecture. With its unparalleled precision and efficiency, it's no wonder that laser cutting has become the go-to method for producing complex designs and intricate details.

What is Laser Cutting?

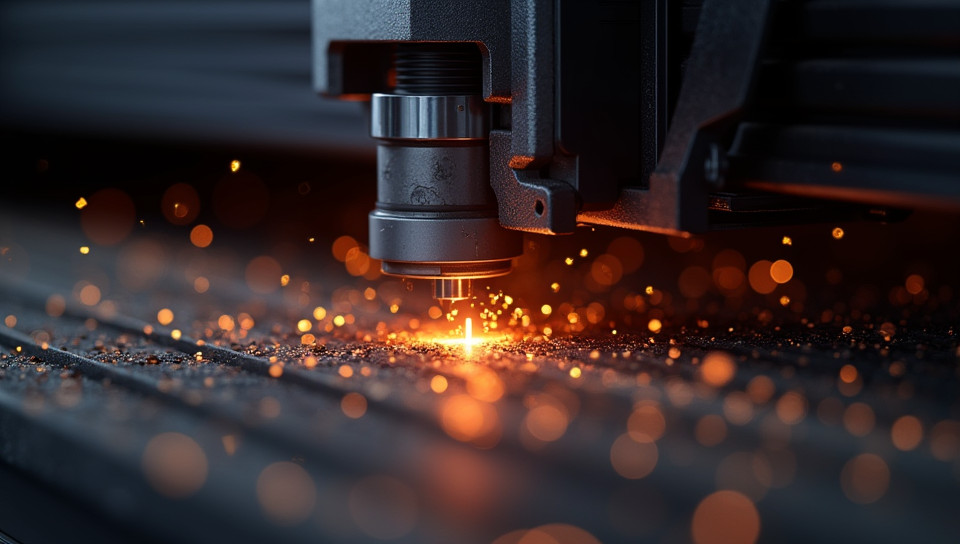

Laser cutting uses a high-powered laser beam to cut through materials such as metal, wood, and plastic with incredible accuracy and speed. This process is made possible by the precision of the laser beam, which can be adjusted to varying power levels to suit different materials and thicknesses.

The Benefits of Laser Cutting

- High precision: Laser cutting allows for incredibly precise cuts, making it ideal for complex designs and small batches.

- Speed: Laser cutting machines are significantly faster than traditional cutting methods, enabling manufacturers to produce more parts in less time.

- Reduced waste: By using a laser beam to cut materials, manufacturers can minimize waste and reduce material costs.

- Flexibility: Laser cutting allows for the use of various materials, including metals, woods, and plastics.

Industry Applications

Laser cutting has far-reaching applications across various industries. Some of the most notable include:

- Aerospace: Where precision-cut components are critical to aircraft safety and performance

- Automotive: Where intricate designs and complex shapes require high-speed production

- Medical devices: Where precise cutting is necessary for surgical instruments and implants

- Architecture: Where laser-cut designs enable creative and complex building structures

Conclusion

Laser cutting has revolutionized industries by offering unparalleled precision, speed, and flexibility. As technology continues to advance, we can expect even more innovative applications of laser cutting in the future. Whether you're a manufacturer, architect, or entrepreneur, understanding the benefits of laser cutting is essential for staying ahead in today's fast-paced market.

- Created by: Krishna Devi

- Created at: Jan. 11, 2025, 11:49 a.m.

- ID: 17640