Microscopic crimps amplify tensile strength 82%

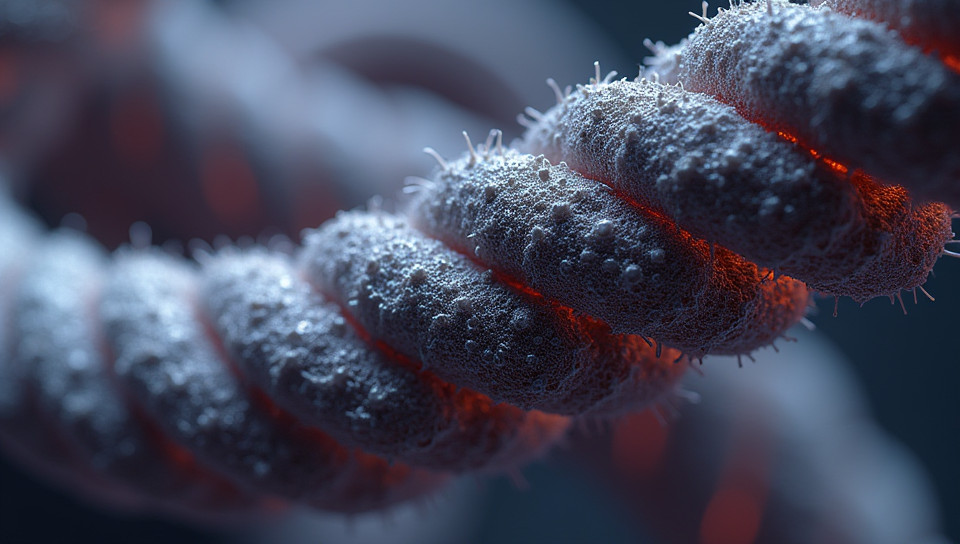

The Hidden Power of Microscopic Crimps

In the world of materials science, there's a subtle yet powerful phenomenon that can make all the difference in the strength and durability of various materials: microscopic crimps. These tiny folds or creases on the surface of materials may seem insignificant at first glance, but they play a crucial role in amplifying tensile strength.

What are Microscopic Crimps?

Microscopic crimps refer to the small wrinkles or creases that occur on the surface of materials when they undergo deformation, such as stretching, compressing, or bending. These crimps can be found on metals, polymers, and even biological tissues. The formation of microscopic crimps is a result of the material's internal structure and its response to external forces.

How do Microscopic Crimps Amplify Tensile Strength?

The tensile strength of a material refers to its ability to withstand pulling forces without breaking or deforming excessively. Microscopic crimps can significantly enhance this property by:

- Distributing stress evenly across the material's surface

- Increasing the material's surface area, which provides more opportunities for atoms and molecules to bond with each other

- Creating microscopic regions of high compressive stress that help to counteract tensile forces

Examples of Materials with Enhanced Tensile Strength due to Microscopic Crimps

Several materials have been engineered or naturally developed to incorporate microscopic crimps, resulting in improved tensile strength. For instance:

- Textiles such as woven fabrics and knitted meshes exhibit increased tensile strength due to the microscopic crimps created by the weaving or knitting process

- Biological tissues like skin and muscle fibers display remarkable tensile strength thanks to their unique microscopic structure and crimping patterns

- Some metals, such as titanium alloys, have been engineered with microscopic crimps to enhance their fatigue resistance and tensile properties

The Significance of Microscopic Crimps in Real-World Applications

The understanding and manipulation of microscopic crimps can lead to significant advances in various industries, including:

- Aerospace engineering: improved materials for aircraft and spacecraft structures

- Biomedical devices: enhanced implantable medical devices with increased durability and strength

- Energy production: advanced materials for wind turbines and other renewable energy applications

Conclusion

In conclusion, the presence of microscopic crimps can significantly amplify tensile strength in various materials. By understanding the underlying mechanisms and exploiting these tiny folds or creases, scientists and engineers can design more robust and efficient materials for a wide range of applications. As research continues to uncover the intricacies of this phenomenon, we can expect to see breakthroughs in fields from aerospace engineering to biomedical devices, all thanks to the hidden power of microscopic crimps.

- Created by: Zion Valdez

- Created at: Jan. 25, 2025, 2:07 p.m.

- ID: 18817