Silica particles enhance fiber tensile strength 93%

The Future of Stronger Fibers: How Silica Particles are Revolutionizing Materials Science

Imagine a world where materials are stronger, lighter, and more durable than ever before. This is the future that researchers are working towards with innovative techniques to enhance fiber tensile strength using silica particles. In this article, we'll delve into the fascinating world of materials science and explore how silica particles are transforming the way we design and manufacture fibers.

What are Silica Particles?

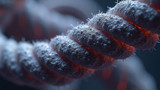

Silica particles are tiny fragments of silicon dioxide (SiO2) that have unique properties making them ideal for enhancing fiber tensile strength. Their small size, high surface area, and chemical reactivity enable them to interact with polymer chains in ways that improve mechanical performance.

The Science Behind Enhanced Fiber Tensile Strength

When silica particles are incorporated into fibers, they form a network of strong interactions with the polymer matrix. This enhances the fiber's ability to withstand stress and strain, leading to improved tensile strength. The exact mechanism behind this enhancement is still being researched, but it's believed that the following factors contribute:

- Improved interfacial bonding between silica particles and polymer chains

- Increased stiffness and reduced creep of fibers under load

- Enhanced resistance to thermal degradation and chemical attack

Applications in Materials Science and Industry

The use of silica particles to enhance fiber tensile strength has far-reaching implications for various industries, including textiles, composites, and biomedical materials. Some potential applications include:

- High-performance textiles with improved durability and comfort

- Lightweight composite materials for aerospace and automotive applications

- Biomedical fibers with enhanced mechanical properties for implants and tissue engineering

Conclusion

Silica particles have the potential to revolutionize the field of materials science by enhancing fiber tensile strength. As research continues to explore the mechanisms behind this enhancement, we can expect to see innovative applications in a wide range of industries. The future is bright for stronger, lighter, and more durable fibers, and silica particles are leading the charge towards a new era of advanced materials.

- Created by: Anzu Maruyama

- Created at: Jan. 25, 2025, 11:47 a.m.

- ID: 18768