The process causes uneven color distribution on surfaces 91%

The Process Causes Uneven Color Distribution on Surfaces

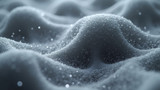

When it comes to creating visually appealing surfaces, color distribution is crucial. However, the process of applying colors or finishes can sometimes lead to uneven results. This issue can be frustrating for manufacturers, designers, and artists who strive for perfection.

Understanding the Problem

Uneven color distribution on surfaces can occur due to various factors. It's essential to identify the root cause to address the issue effectively. Here are some common reasons:

- Inconsistent application of materials or coatings

- Insufficient drying time between coats

- Incorrect temperature and humidity conditions during application

- Poor surface preparation before applying colors or finishes

Causes of Uneven Color Distribution

Physical Factors

Physical factors such as roughness, texture, and porosity of the surface can contribute to uneven color distribution. These characteristics can affect how colors adhere to the surface, leading to inconsistent results.

Chemical Factors

Chemical reactions between materials, coatings, or finishes can also cause uneven color distribution. Incompatibility between substances or incorrect ratios of components can lead to unpredictable outcomes.

The Impact on Various Industries

Uneven color distribution on surfaces affects multiple industries, including:

- Coatings and paints

- Furniture manufacturing

- Automotive industry

- Textiles and fashion

- Construction and architecture

Solutions to the Problem

To overcome uneven color distribution on surfaces, consider the following strategies:

- Implement quality control measures to ensure consistent application of materials or coatings

- Follow established guidelines for drying time and temperature conditions

- Optimize surface preparation techniques before applying colors or finishes

- Experiment with different materials or coatings to achieve desired results

Conclusion

Uneven color distribution on surfaces is a common issue that affects various industries. By understanding the causes, implementing quality control measures, and optimizing surface preparation techniques, manufacturers, designers, and artists can produce visually appealing surfaces with consistent color distribution.

- Created by: Benjamin Kelly

- Created at: Dec. 25, 2024, 11:29 a.m.

- ID: 17082